All products

Highlights

Guide

This text is machine translated.

Useful information about electromechanics

Electromechanics deals with the interaction of electrical and mechanical processes and is the basis for the functioning of numerous electrically operated systems and devices. Electromechanical drives in particular offer many advantages compared to their hydraulic and pneumatic counterparts. In our guide you will learn more about the structure and application areas of electromechanical components.

-

General information on electromechanics

-

Electromechanical components at a glance

-

Our practical tip: Securely fit electromechanical components

-

Purchase criteria for electromechanical components - what is important?

-

FAQ - Frequently asked questions about electromechanics

-

Our most popular guides in the field of electromechanics

General information on electromechanics

Electromechanics is a specialist area associated with electrical engineering, which has the content of converting electrical to mechanical energy and vice versa. Mechanical processes are not generated in the electromechanics by means of fluids, as is the case in hydraulics and pneumatics, but by means of electric drives and magnetism. Hydraulic drives have been preferred for a long time, especially for demanding tasks, such as transporting heavy loads. However, electromechanical drives are now also good, if not better, for this purpose. Compared to hydraulic drive systems, they are often smaller and lighter in size, because they only have an electric motor and do not require pumps, tanks, pipes and other components typical of hydraulic systems. Electrical drives operate more quietly, have a larger speed range and are suitable for tasks requiring precise positioning. In addition, electromechanical components can be embedded more easily in electronic controls than hydraulic ones. Many companies have recognized this and are increasingly using electromechanical drives for production and production purposes.

The area of electro-mechanics cannot be clearly defined, but has points of contact with other special disciplines, in particular electronics and mechanics, but also with mechanical engineering and information technology. Electromechanical systems have now arrived in many areas and are used, for example, in the manufacture of precision and measuring instruments, in electroacoustics (loudspeakers), medical technology as well as in sensor and actuator technology.

Electromechanical components at a glance

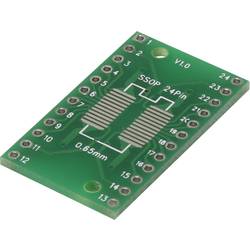

Electromechanical components form the basis of an electromechanical system. No electrically operated device would work without it. There are a variety of electromechanical components, each designed for special applications. Circuit boards, are used, for example, to secure components of an electronic circuit in a specific arrangement and to establish an electrical connection between them. They consist of an insulating material, usually fiber-reinforced plastic, and have a thin copper layer on the underside. The components, such as transistors, capacitors or resistors, are either soldered to the circuit board or simply plugged on, if this is a breadboard.

Mechanical processes are often generated in electromechanics using magnetism. Speakers, for example, are equipped with electromagnets and permanent magnets that attract and repel each other, thereby moving the loudspeaker membrane. Electrical signals are thus converted into mechanical vibrations and finally converted into acoustic signals.

Magnets are found in many other electromechanical applications, for example in bells, door-buzzer and similar electrical installations.

Magnetism also plays a role in the development of electromechanical relays (EMR). These are two-position switches that can be used to switch a circuit on and off. The function is based on electromagnetic force generated in a coil. Depending on the type of contacts (NC or NO), the circuit is established or interrupted. Relays are used to switch load circuits and can serve as switching amplifiers. A well-known example is the automotive relay.

Switches and pushbuttons are used to control electromechanical applications. They can be used to open, maintain and close electrical connections. There are manually operated switches such as shift or tilt and rocker switches and those that can be operated without manual action by means of special mechanics, magnetic force, temperature or position changes. An example of position switches are limit switches that trigger the switching process when a certain end position is reached and, for example, interrupt the power supply. The so-called contactors are a special form of switches.

An electromechanical contactor is very similar to a relay in terms of its design and operation, but designed for higher switching power and can provide a greater mechanical switching force. For this reason, contactors are ideal for high-performance applications and are primarily used in industry. Although their name suggests something else at first glance, contactors do not provide protection against overload or short circuits.

This task is performed by backups. They are integrated into the electronic circuit and interrupt the circuit or power supply as soon as a certain current is exceeded. This prevents damage to the electrical installation.

In many cases, electromechanical components are installed in a housing. A housing protects the internal electronics and should be adapted to the respective application in terms of equipment and design. In addition to standardized 19-inch racks that act as holding devices and are used in industry and trade, there are housings for wall mounting, table housings, plug housings and many other designs that are well suited for hobby constructors and small applications.

Our practical tip: Securely fit electromechanical components

In order to provide sufficient protection for the electronics, the housing must be adapted to the respective ambient and working conditions. If it is placed outdoors, it is exposed to external factors such as wind, water and dirt to which it must be withstood. In this context, a suitable IP degree of protection must be observed. For orientation: The IP68 degree of protection (protection against dust, contact and permanent immersion) is currently the highest. It is also important that the housing is not a source of interference for other devices and is protected against interference (electromagnetic fields or waves). For safety reasons, it should be standardized in accordance with the EMC directive (EMC = electromagnetic compatibility).

Purchasing criteria for electromechanical components – what is important?

Before purchasing, it is important to consider which electromechanical component is best suited for the particular application. Contactors, for example, are available in several designs.

While contactors can be used in a wide range of applications, reversing contactors are particularly suitable for special applications, for example in conjunction with three-phase motors. Solid state contactors are the right choice when fast switching and low-noise operation is required, and are used in motion, heating, power and lighting control, among other things.

For example, the selection of acoustic components is also extensive. If you choose to purchase a transducer or small speaker, you must pay attention to the required voltage, impedance (AC resistance in ohms), and resonance frequency (specified in hertz). However, the level of noise (specified in decibels) and the tone type (continuous, interval or siren tone) must also be determined in advance.

Ease of use can also play a role in the selection of an electromechanical component. This is the case, for example, for PCBs. If you do not have any expertise in handling the soldering iron or simply want to save yourself from soldering, access plug boards that are much easier to handle.

Quality and processing are in any case important purchasing criteria on which private individuals and companies should place equal value. High quality is usually accompanied by a high level of functionality, a long service life and a reliable working method, was the best prerequisites for smooth processes in production and production.

FAQ – Frequently asked questions about electromechanics

What is the relationship between electromechanics and mechatronics?

Mechatronics has many points of contact with electromechanics, but goes beyond that. It is an interdisciplinary field that unites the three disciplines of mechanical engineering, electrical engineering and computer science and uses their methods to solve technical problems. In mechatronics, systems work mechanically in Kern, but are supported by technology (computer technologies and electronic systems).

Do all electromechanical components ich use have to be from the same manufacturer?

No. However, if you have consistently had good experience with a manufacturer, are convinced of the quality of its products and prefer to rely solely on its range for safety, this is certainly not a disadvantage. It has no influence on the functionality of the technology if you use components from different manufacturers. There are many companies that offer products of the same or similar high quality.

Our most popular guides in the field of electromechanics

| Guide | Area | |

|---|---|---|

| 1 | Switches & buttons | Switches & buttons |

| 2 | Push switches & buttons | Switches & buttons |

| 3 | Micro Fuses | Fuses |

| 4 | Universal casing | Covers |

| 5 | Rotary Switches | Switches & buttons |

| 6 | printed circuit boards | PCBs |

| 7 | Micro Switches | Switches & buttons |

| 8 | Relays | Relays |

| 9 | Rocker Switches | Switches & buttons |

| 10 | Automotive Switches | Switches & buttons |

| 11 | Fuse Holders | Fuses |

| 12 | Toggle Switches | Switches & buttons |

| 13 | Tilt Switches | Switches & buttons |

| 14 | Position Switches | Switches & buttons |

| 15 | Automotive Relays | Relays |